Cargo and container ships, as well as offshore platforms (primarily dedicated to oil or gas extraction), require efficient ventilation systems to prevent condensation, dissipate gases, and remove heat. This is especially important if the cargo generates heat or poses a combustion risk. In such cases, ventilation not only protects the transported goods and the integrity of the vessel but is also vital for the crew's safety.

Marine environments present extreme conditions, such as high humidity, salinity, heat, corrosive substances, and constant vibrations, which often occur simultaneously. It is common for barges to transport chemicals that must be ventilated properly to avoid risks. Ventilation is key in various types of vessels, such as:

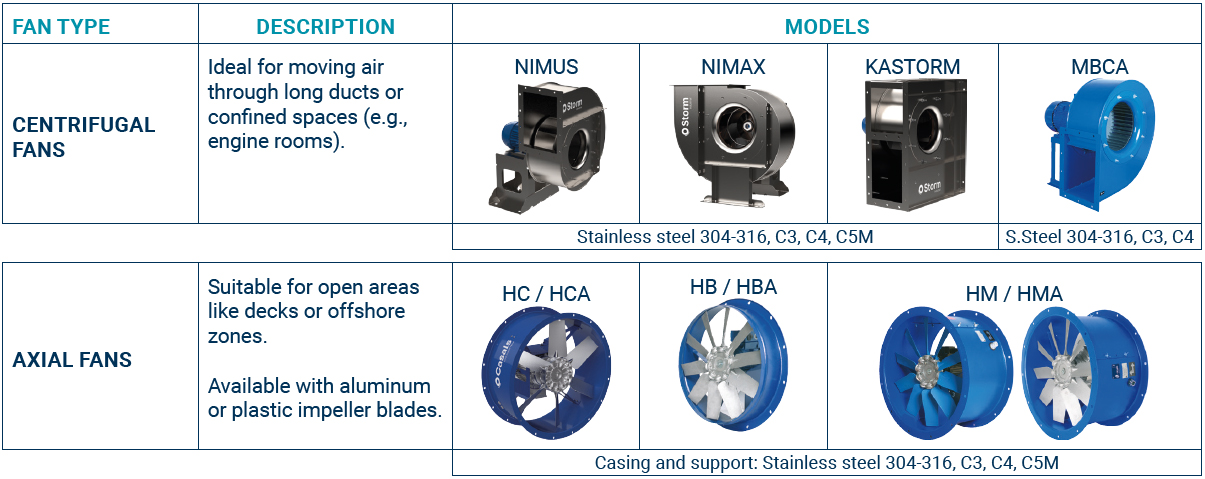

Casals Ventilación offers a wide range of fans specifically designed for marine and offshore applications, including:

Fans used in marine environments must be prepared to withstand highly corrosive conditions. Casals Ventilación offers centrifugal fans made from stainless steel or with marine-grade finishes, such as C3, C4, and C5M, according to the ISO 12944 standard:

Marine service motors are essential in various applications, including military vessels, offshore platforms, and passenger and cargo ships. These motors are designed to operate in extreme conditions, such as salt-laden atmospheres, constant humidity, and corrosive environments.

Options for marine motor certifications:

Where are ATEX fans required?

In marine applications, installing ATEX-certified fans is crucial where there is a risk of explosions due to the presence of explosive atmospheres, which can be generated by flammable gases, vapours, or dust.

Below are specific examples:

Medium pressure Casals fan with simple aspiration and direct coupling. Robust, compact and cubic. To move clean or dusty air. Self-cleaning impeller and high-performance backward reinforced blade impeller.

> more information

Short-cased fan with variable pitch blades, with reinforced and painted steel casing to protect against corrosion. Modular motor-impeller assembly to make it more versatile in case of replacement. For air renewal and smoke extraction up to 50ºC.

> more information